For serious wine collectors keeping those liquid gems at a temperature and humidity where they live happily until consumed is a crucial factor both in the design and construction of a wine closet and in choosing suitable door hardware.

Wine kept for future consumption needs to be in a cool dark cabinet that is kept to a temperature of 45-65 degrees with a controlled humidity of about 70%. It is also important to keep wine free from vibration as this will disturb the sediment in the bottle as well as setting off a chemical reaction that decreases the wines acids thereby dulling the wines flavor. While minor vibration may be easier to control, in California the vibrations are often seismic!

Do the specific requirements for wine storage limit the customers choice of door handle?

The simple answer is no, choosing the right type of handle for a wine cabinet door should be no more taxing than selecting a handle for any interior door. The same factors need to be considered and questions answered;

Door handing

Functioning latching handles versus fixed

Width of door stile

Door Handing

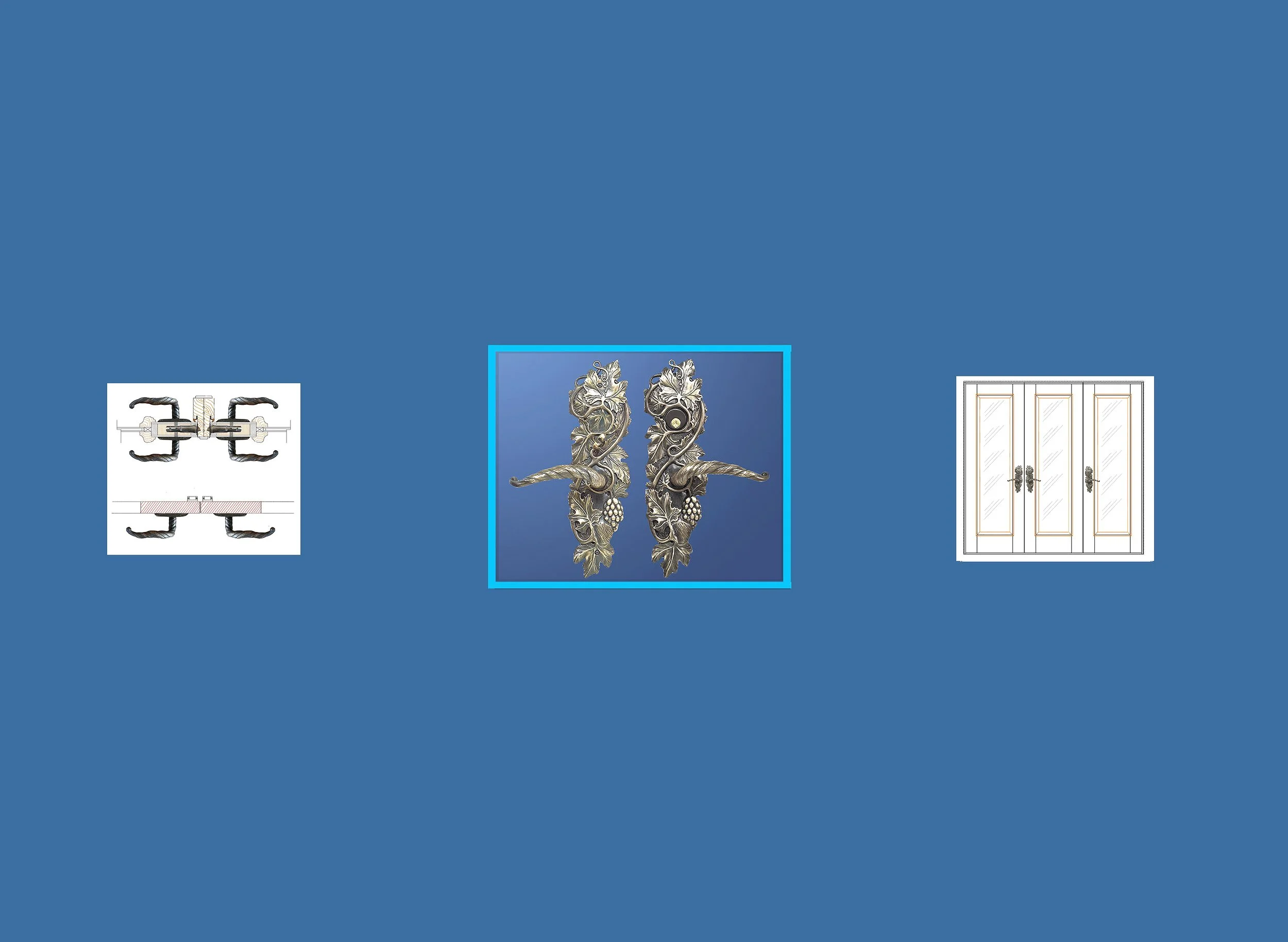

Looking at the door from the outside, doors that hinge on the left are left-handed and those that hinge on the right are right-handed and this holds true for double doors. Some wine closets are made with a pivot hinge that attaches to the top and bottom of the door with a pin rod, see photo below.

Whatever the hinge type it needs to be strong enough to ensure that the door(s) when closed, tightly fit into the cabinet frame to help maintain a constant temperature. Wine cabinets and wine racks are often made to pitch backwards which helps prevent the wine from touching the cork and also gives a gentle gravity tug that helps the doors to firmly close.

Functioning or non-operative levers/pull

This brings up the question of cabinet construction and the presence of a center divide. A center divide is a wood divide that runs from the top to the bottom of the cabinet frame. A center divide of at least 1 1/2”is critical for double doors if they are required to latch with a tubular latch. A tubular latch is activated by the lever which throws the latch tongue into the strike on the side of the divide. Cabinets can be made with a hydraulic hinge closure which creates a tight hermetic seal that does not require a latching operational handle. If the double doors are flush without a divide then magnetic latches attached to the top and bottom of the doors and cabinet frame are a good option. Roller latches are another option but the roller ball and strike tend to wear out and the roller springs tend to loose their tensile strength so will need to be adjusted periodically. The plan view in the above diagram shows how the tubular latch and magnetic differ.

Stile Width and Backset

Our standard backplates are 3” wide and require a net stile width of 5” for a 2 3/8” backset. For smaller stiles our multi-point backplates are 2 1/8” or 2 ¼” wide and require a 3 ½” net stile. The width is referred to as net to denote the free flat surface of the door frame without any door molding or astragal.

I wrote this piece in response to a consumer whose tenacity and diligence proved indispensable in the correct ordering of our vine door handles. Ordering door handles should not require a degree in engineering and should not be an arduous task so my advise is to check and double check the door specs supplied and don’t hesitate to ask the hardware manufacturer for help in ordering the right type of handle and latch.