Can you put new handles on an old door?

Last month we escaped the confines of our Covid reality and travelled to Florence Italy where the food and scenery were all that we remembered.

Craving fine seafood, we did a google search and dined at Marina Di Santosprito on via Maffia. The seafood lived up to the rave reviews but what was unexpected was the bathroom door lock. The street name and the fact that diners had to knock at the front door to gain access, should have been our first clue.

Martin had already photographed the skilled filleting of our snapper but he returned from the bathroom with a surprising photograph of the door lock and handle.

Marina Di Santosprito on via Maffia, Firenze,Italy

The outside of the door was handle-less and was simply pushed to open but the inside had a long retrofitting history where wood patches were used to rustically plug holes left by previous hardware.

Not quite the look you had in mind.

Things to consider when changing out a door knob set

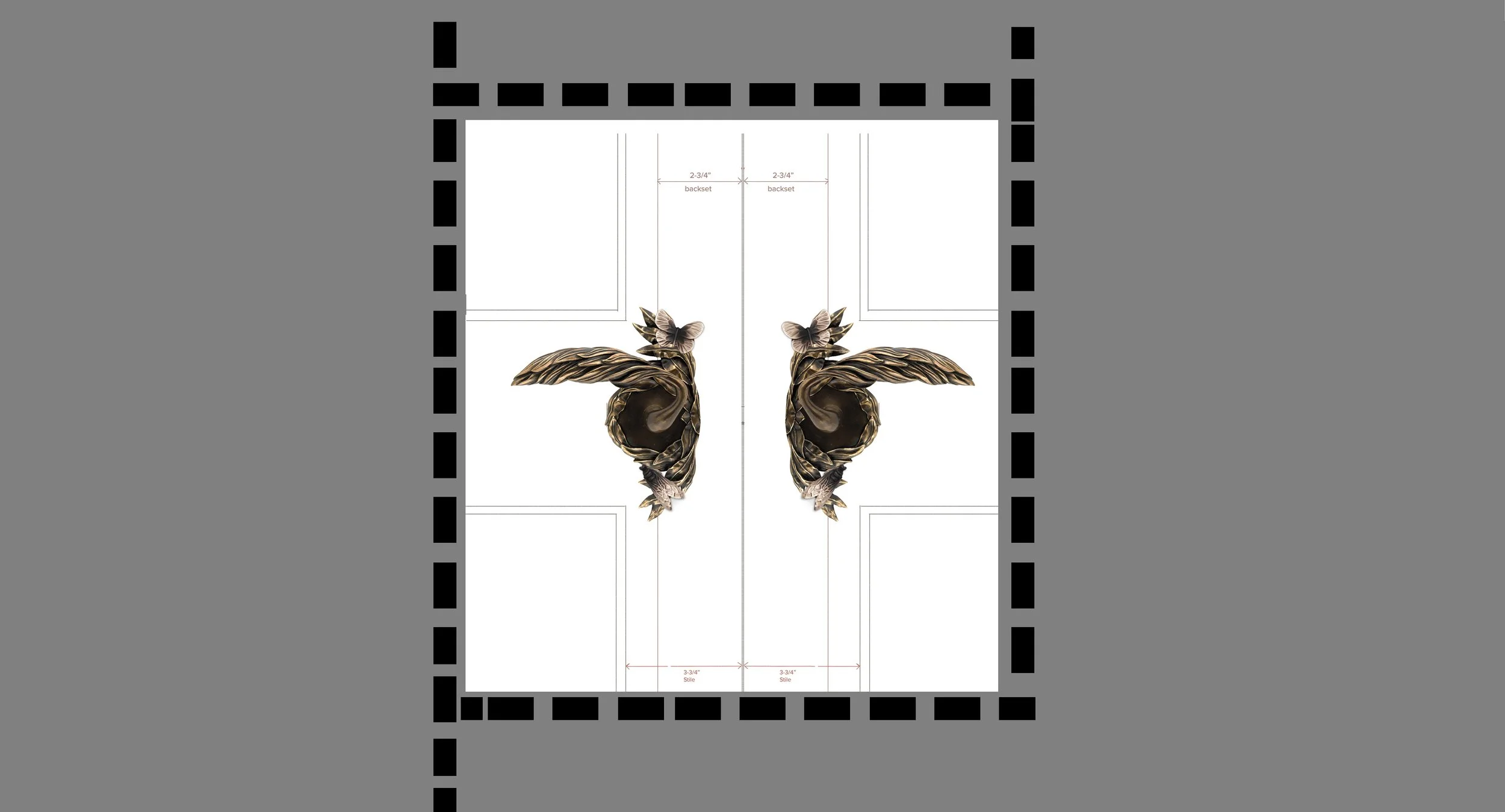

Most standard doors will be pre-bored with a 2” that will be centered at 2 3/8” distance from the door edge, this is the backset. Some door makers may position the bore at 2 ¾” if the door stile is wide enough and for custom doors order latches at 3” or greater can be special ordered.

The tubular latch is the mechanism that when thrown holds the door closed. The latch will be configured for use with a pair of knobs or levers. At the center of the latch is a small square port and through this the spindle or square rod passes connecting one knob or lever to it’s mate.

Door pre-drilled with a 2” bore hole, square hole in latch is where the spindle is inserted through the latch mechanism. Rose escutcheons are attached firmly to each other by a screw that passes through the threaded posts on the back of each rose.

The spindle is inserted into the back of one cat door knob, passes through the latch port and into the back of the other cat knob and is secured by a small Allen screw on the side of the cat head.

Other holes to consider

Back-plate holes

The tubular latch will fit within the existing bore hole and even the most minimal rose should cover the larger 2” bore. There may be other holes above and below the bore where bolts were used to connect the front and back door plates or there may be smaller wood screw holes where the backplates were connected by surface screws to the face of the door. Either way you will need a larger backplate that is tall enough to cover these.

Rose escutcheon

The rose trim for a knob or lever is typically smaller than a backplate and we make ours with 3” diameter. We make each rose so that it can be connected to its mate through 2 connected rods that are positioned on the back of the rose at a center to center of 1 5/8”. Our rods are solid bronze and are machined for 8/32 thread screws. A connecting screw/bolt passes though the faceplate into the first rod and continues into the back of the second rod. The connection is made within the 2” bore so no additional holes will be made and hopefully the decorative trim at 3” will cover any existing holes. If not consider using a handle set with a backplate.

Molding to consider

While a larger backplate may seem the obvious option as it will cover most existing holes the available space may be limited by the molding around a door panel or by an astragal trim that is attached to the edge of a pair of doors.