As the global supply chain challenges are still with us we, like many, are finding ways to re-tool some hardware designs so that we are not reliant on overseas suppliers. All of our work, meaning our castings are made locally by us here in Los Angeles. From the initial creation of the pattern to mold development, to pouring wax and then bronze or steel the process is local and the materials if not local are certainly American made.

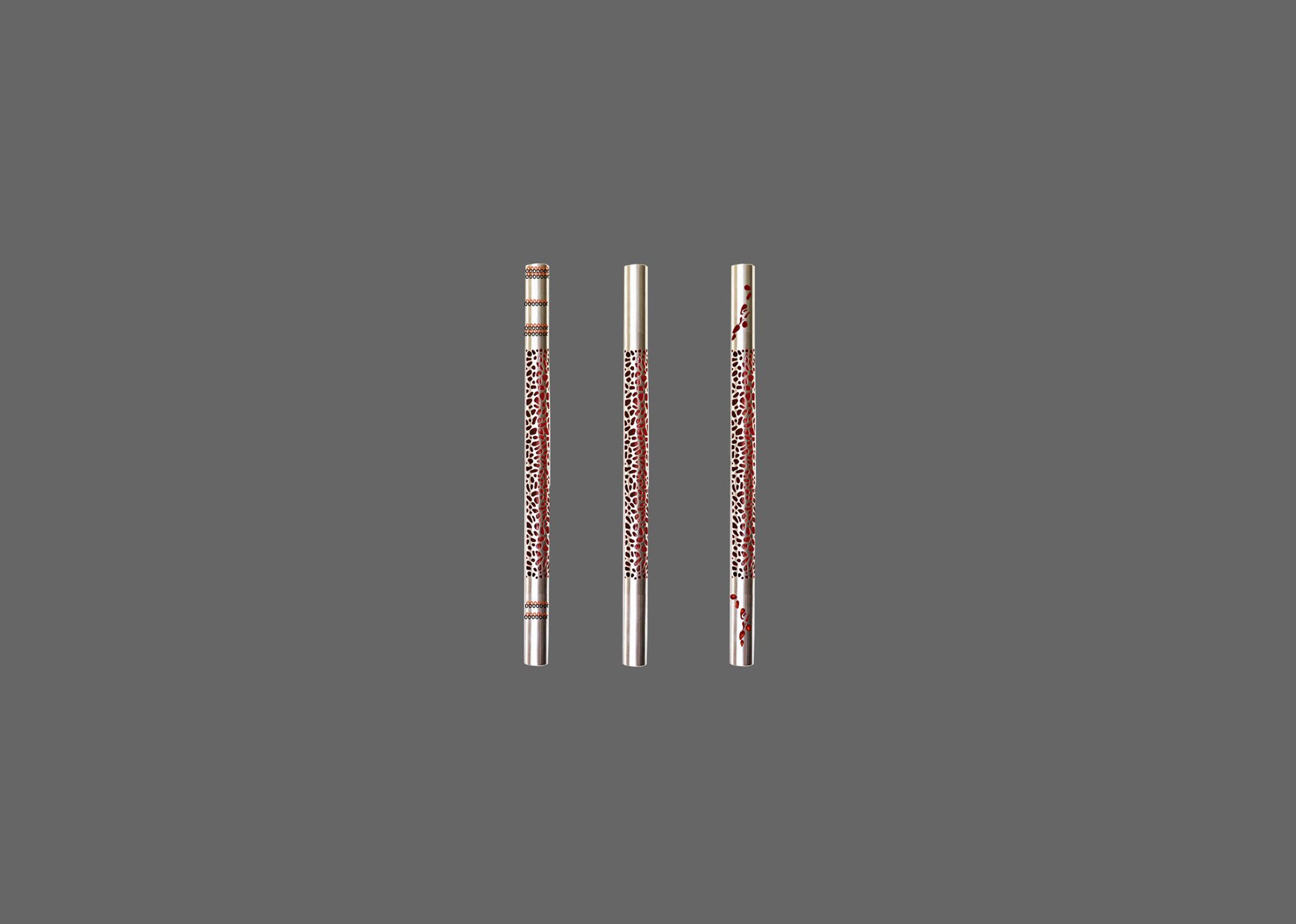

There is one area though where we have relied on LED components in our illuminated door handles and so are transitioning away from lighting our handles to finding more creative and less high-tech ways of adding a dash of sparkle to designs, which in their own right, do not actually need embellishing. Simply put we are phasing out colored LED and replacing this with powder coating.

Benefits of new direction

The main advantage is the flexibility with which a piece can be powder coated. Powder coating can be applied to almost any part of a handle which allow for color to be integrated in a much more artistic and organic way. This is especially the case with the Morphic pieces.

When we created the LED pieces we had assumed that eventually we could move away from direct wired electric power to long life batteries that would be small enough to fit inside the fixture. This did not occur and the resulting market was very small.

By moving away from LED products we are able to lower the consumer price just a little as we no longer will be buying the components and we will no longer be paying the costly testing and regulatory fees charged by UL.