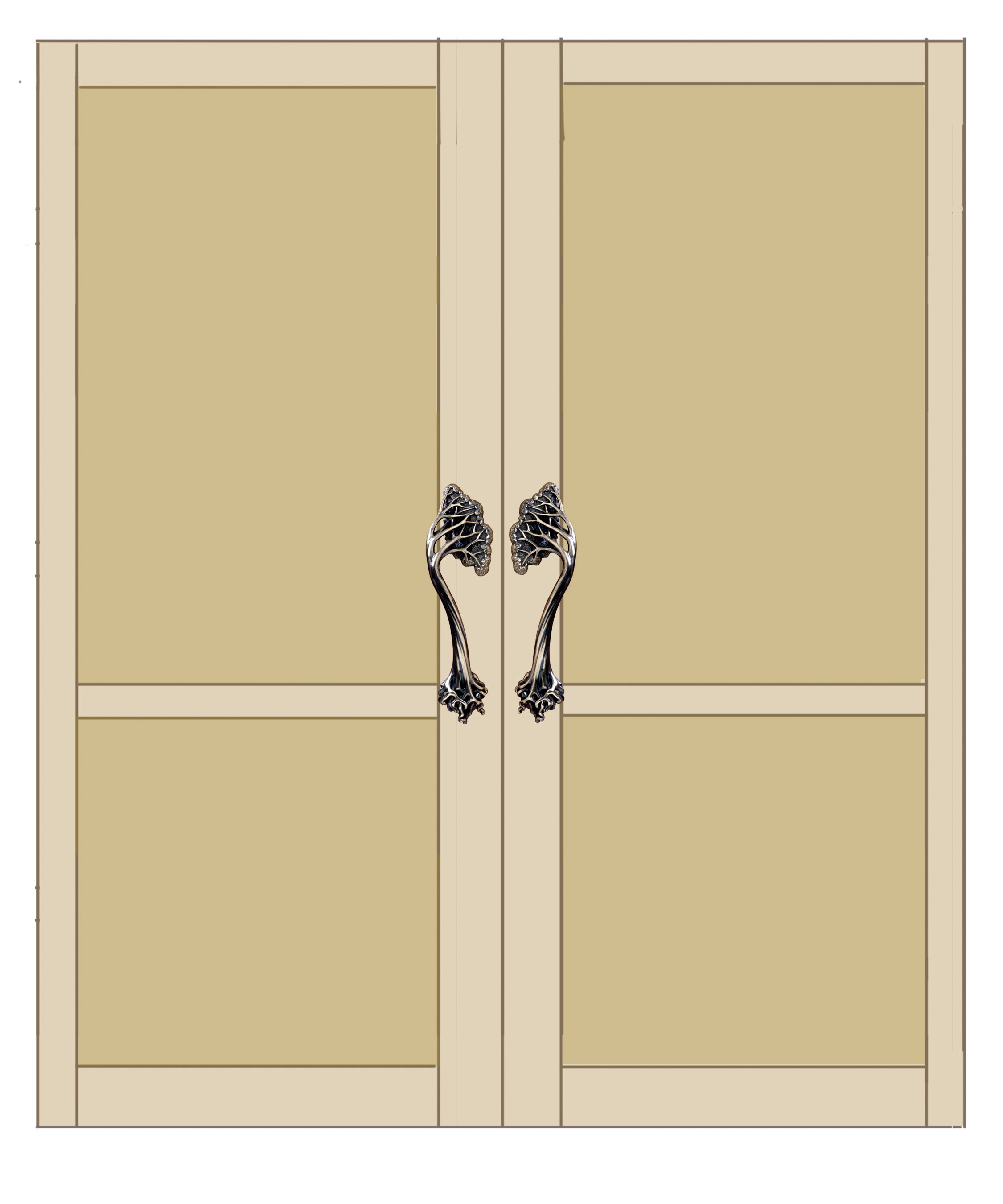

The Orchid collection of cabinet and vanity pulls has a new member, the hanging orchid door pull. The piece is a hybrid orchid and loosely based on the large full leaves of the lepantes orchid and the lush flowers of the cymbidium family. Many cymbidium members have large protruding labellum (lip) balanced by full side and top sepals. While all orchids are arguably beautiful the cymbidium’s balance and fullness give it an undeniable elegance and the sturdy leaves of the lepantes when cast in bronze or stainless steel make for a perfect flower mount as well as back-plate. The back-plate curves outwards to support the flowers and the tapered and flat ends each have a threaded post for easy screwing from the back of the door. The posts have a 15” center to center and the overall length is 16”. We chose to finish the supporting leaf in dark antique oil and to make the flowers and center leaf ridge a lighter finish and have now created a hybrid finish code DLA to describe this appearance.

Other members of this collection were inspired by the Venus Slipper and Moth orchid with sizes ranging from small 2'“W orchid knobs to 8”W orchid stem pulls. The image below shows the larger pieces in a brushed bronze with light antique finish with the small knob in a brushed nickel finish.

The small knob and leaf from the hanging orchid can be used to create a custom spray for vanities as wide 6’.