We recently attended the 3D Printer World Expo held at the Marriott convention center in. Burbank California, which was very interesting and enlightening.

At present Martin is sculpting and creating the old fashioned way:

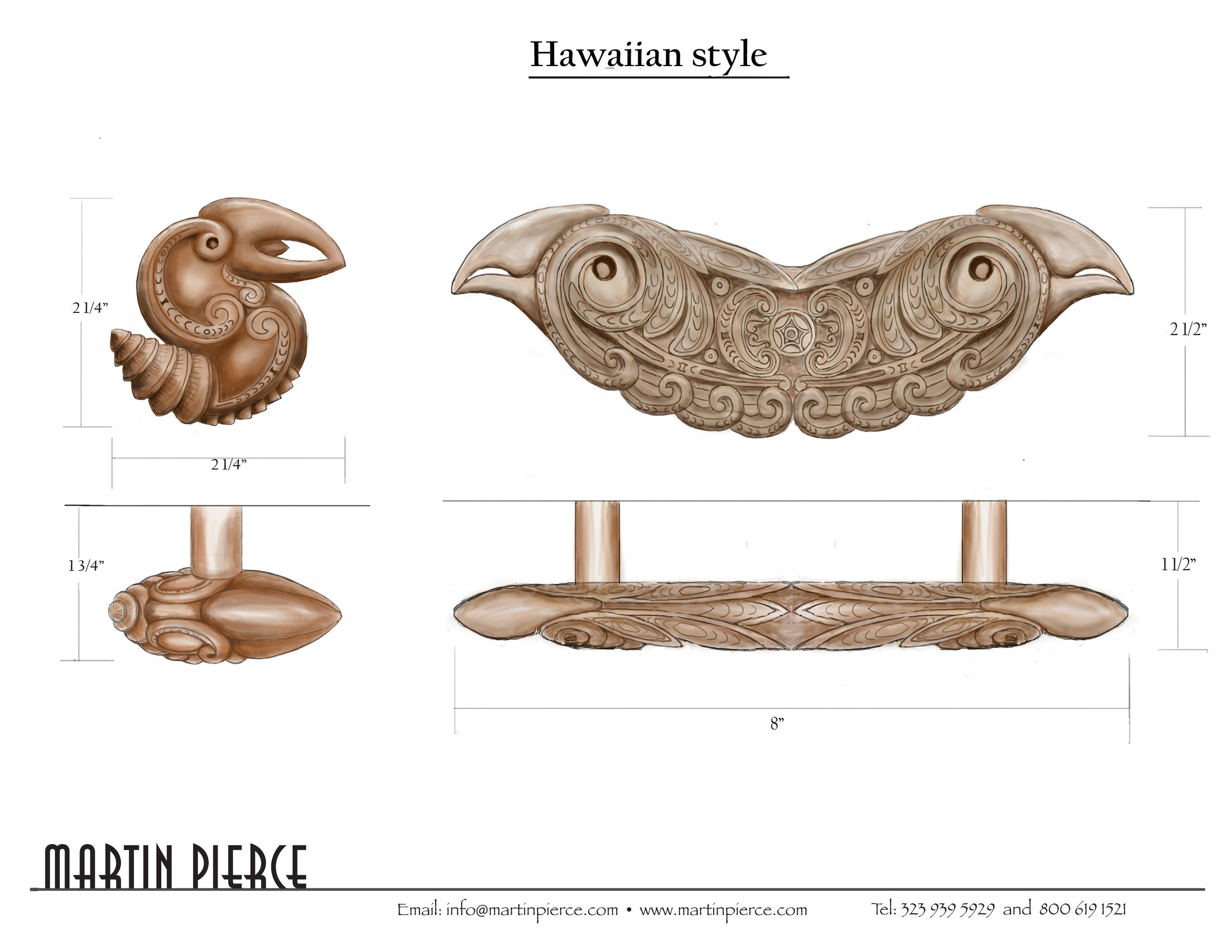

- Sketch by hand an idea showing it from 3 perspectives or elevations.

- Draw over each elevation on a 1"x 1" square grid

-

- Use a sheet of tracing paper to make a grid that is twice as big as the first grid i.e. 2" x 2" squares to make our initial sketch twice as big by free hand drawing the same lines on the bigger grid and so on for all the grid sections. We will continue this process for all 3 perspectives.

- We then take the tracing paper elevations or perspectives and trace them onto a block of wax or wood

- Finally we begin to shape the piece with cutting tools, basically bandsaws, chisels etc.

As far as I can tell, this "old-fashioned" grid concept is at the heart of 3D printing and 3D scanning. We have all seen enough movies or games where we see a human head mapped out on a rotating grid and then the model gains life with skin and muscle being digitally added. So it was fun and enlightening to see some of these model making and scanning machines in action.

Gil Bruvel had some really interesting sculptures on display:

What ideas did we take away and what lessons were learnt?

COST and LEARNING CURVE

The 3d scene is becoming more affordable. The base price of a 3D printer, for example the creatorbot-3d machine, is priced at $1,845 and will print a piece in polycarbonate or nylon that is 12"w x 12"d x 18"h. Not bad but you will also need to be able to "build" the stl file that "runs" the printer or issues the instructions or code that determines how it moves and releases jets of polycarbonate to create the shape of the piece you want to make. To be good at this you will need to learn a program like zbrush or maya or Sketch up. The first 2 programs run anywhere from $699 to $2000 plus but Sketch up is free.

If, like me, you find an on-line tutorial difficult there is a 40 hour course for $1500 available. BUT whether these costs add up will depend on how you can use what is printed.

PATTERN MAKING

If you are starting from scratch and do not have drawing and sculpting skills then yes, 3D printing and modeling are good options. However, for us the learning curve is too long and the output too slow when compared to old fashioned carving and modeling. When Martin has a new concept he is able to draw it very quickly from at least 3 perspectives. He can make a rough model in modeling foam to see if the actual piece in reality is still attractive and at that point can make changes. By comparison, if he created a 3D file it would take him a long time to create the file as his keyboard and mouse skills are slow, it would also take as much as 12 hours to print the piece. If he then wanted to change it he would have to go back to his digital file and work at his snail pace to make the changes and then spend again up to 12 hours printing it. This process may have to be repeated several times.

MAKING A FINISHED PRODUCT

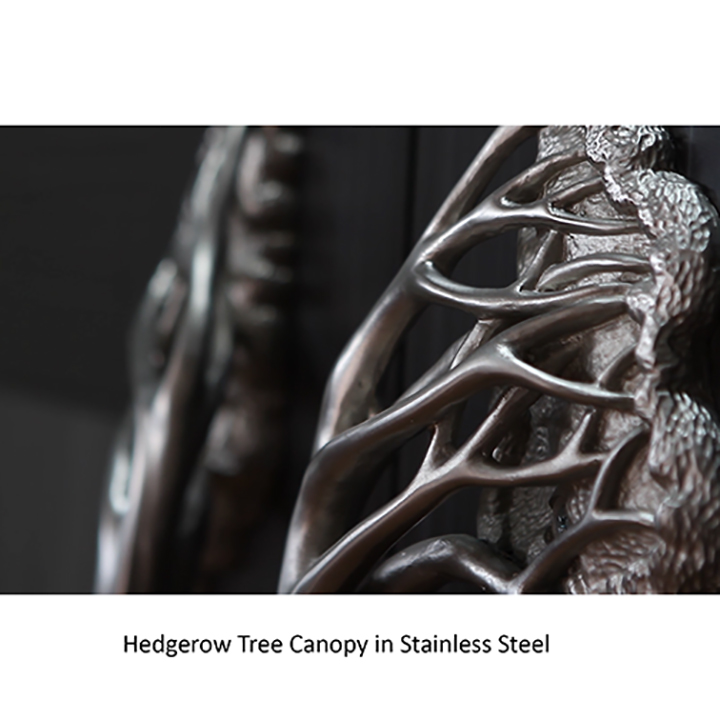

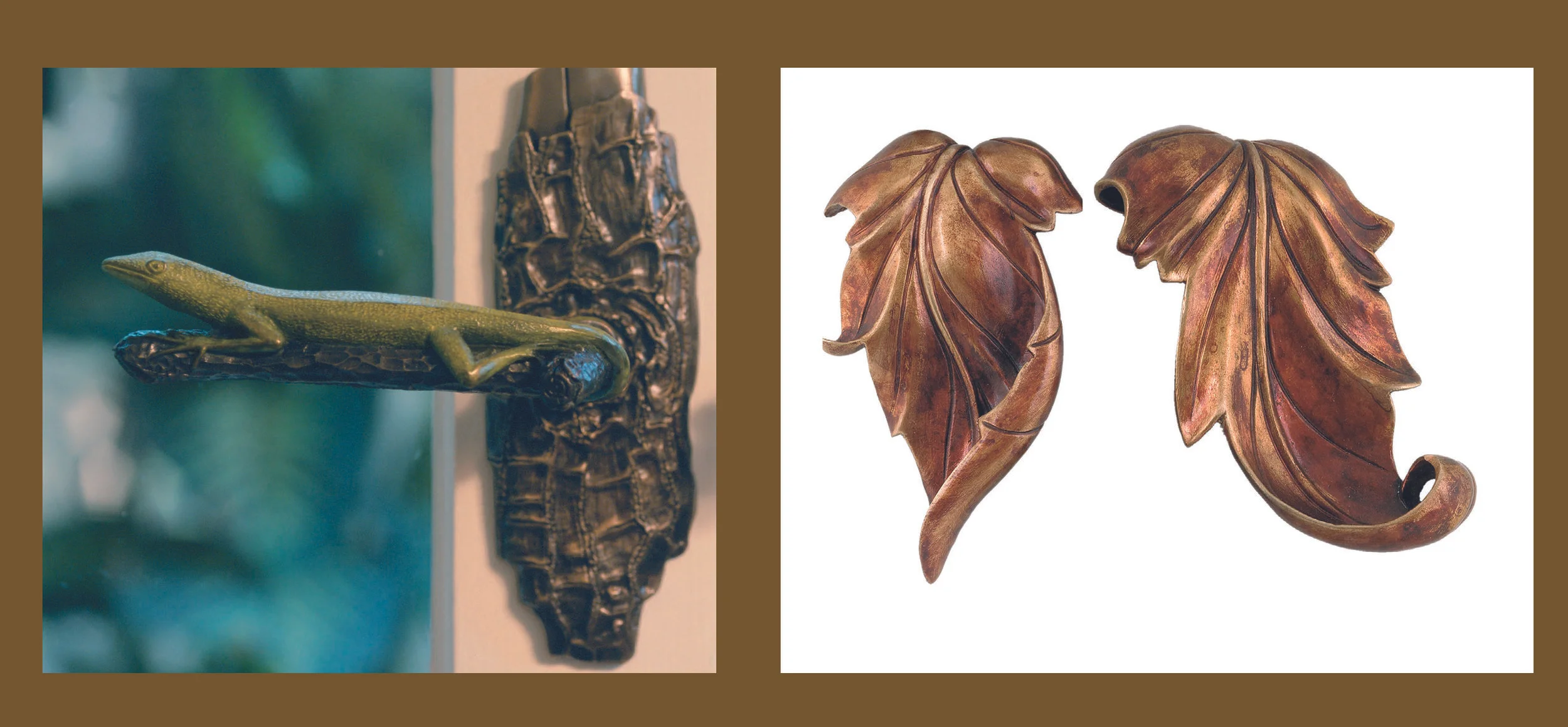

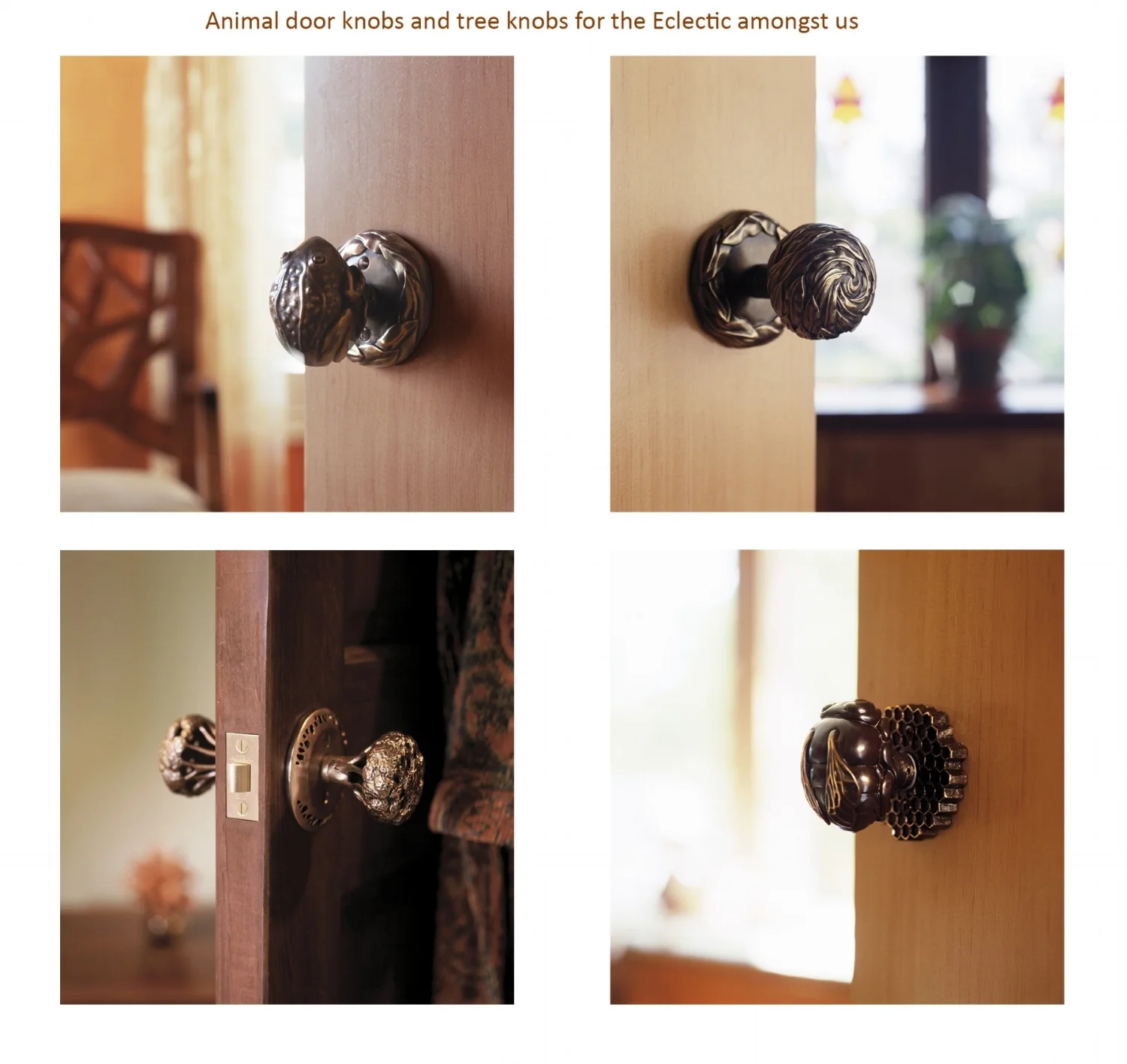

There are some 3D printers that can print metal using essentially fine metal flakes that are mixed in a polymer so the end result is at best a metal hybrid. Not an option for Martin as we cast our bronze door handles in SOLID silicon bronze and likewise our contemporary door handles using SOLID 316 stainless steel. Both metals are dense, not porous, and have great durability. They stand on their own as metals and do not need to be plated. 316 Stainless steel is also one of the most corrosive resistant metals around. We value the inherent beauty of solid bronze and solid steel and both give us the mediums we need to create beautifully crafted heirloom hardware.

HOW WE USE THE TECHNOLOGY

We are currently using this technology to scan simple shapes like our new Dragon egg. Martin turned it on a lathe to create a solid egg shape in wood approximately 14" long by 6" in diameter. To hollow out the wooden egg would have taken Martin 2 to 3 days so we chose to work with a 3D scanning company who scanned the egg and then created an stl file in which they made the egg hollow with a thin wall dimension of .125" . We then worked with a 3D printing company who printed the new hollow egg in a polycarbonate material. This saved us a lot of time and we will use this process again to create blank patterns. The egg has since been carved with what we hope others will agree, is fine artistry, and will be cast in solid .125" steel. It will be our first venture into custom wall lighting and we are excited to debut it for he hospitality designers and architects who attend the upcoming 2015 HD Expo in Las Vegas.

To view our entire collection of stainless steel and bronze hardware, please visit our site at www.martinpierce.com.