As a small, hands- on company, it is not difficult to spot trends at their out-start.

This is certainly the case with recent orders for barn door handles that are two tone with black or very dark brown accents. Our large door pulls, or grips are available in silicon bronze, an alloy that is golden or champagne in its unadorned state and in 316 stainless steel, an alloy which is a cool grey when cast.

Both alloys are durable, rust resistant and high- quality mediums but their density dictates how each can be color accented. Stainless steel is a much harder medium than bronze and its surface is more difficult to penetrate so liquid patinas will tend to slough off and not adhere to the metal. While bronze is a strong alloy its surface is easier to buff so liquid patinas can more easily penetrate and bind to the alloy.

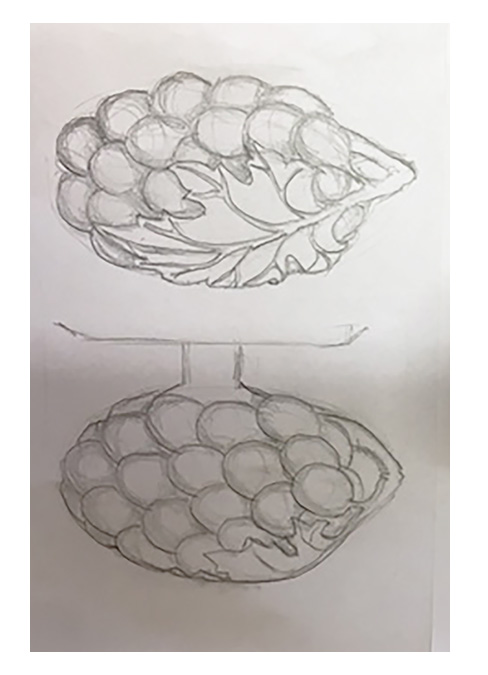

Black is the color of choice for most tracking currently being sold for sliding barn doors which explains why we are seeing an increasing demand for black highlights to be added as custom finishes to our steel and bronze door grips. As our large door handles are dramatic organic designs, we feel it is important that the color accent be integrated into the design. When we are adding a dark patina to bronze handles, we immerse the piece in a chemical solution until it reaches the required darkness and then we halt the process by immersing the handle in water. Once dry, we re-work the piece by hand sanding and buffing the piece in select areas to remove the dark patina. The process can be repeated so that different depths of color are created. Once complete the color is fixed with penetrating oils and with a hard-wax topcoat. For high traffic projects the handle can be further protected by baking on a clear enamel coating.

We add color to stainless steel by baking on a powder chosen for color and iridescence. The handle is buffed or polished to the desired luster and areas that are to be free of color are masked off from areas receiving color. The color powder is sprayed on to the piece and then baked. Determining the accented area is crucial as once baked it is extremely difficult to rework the finish without stripping the piece back to the base metal.