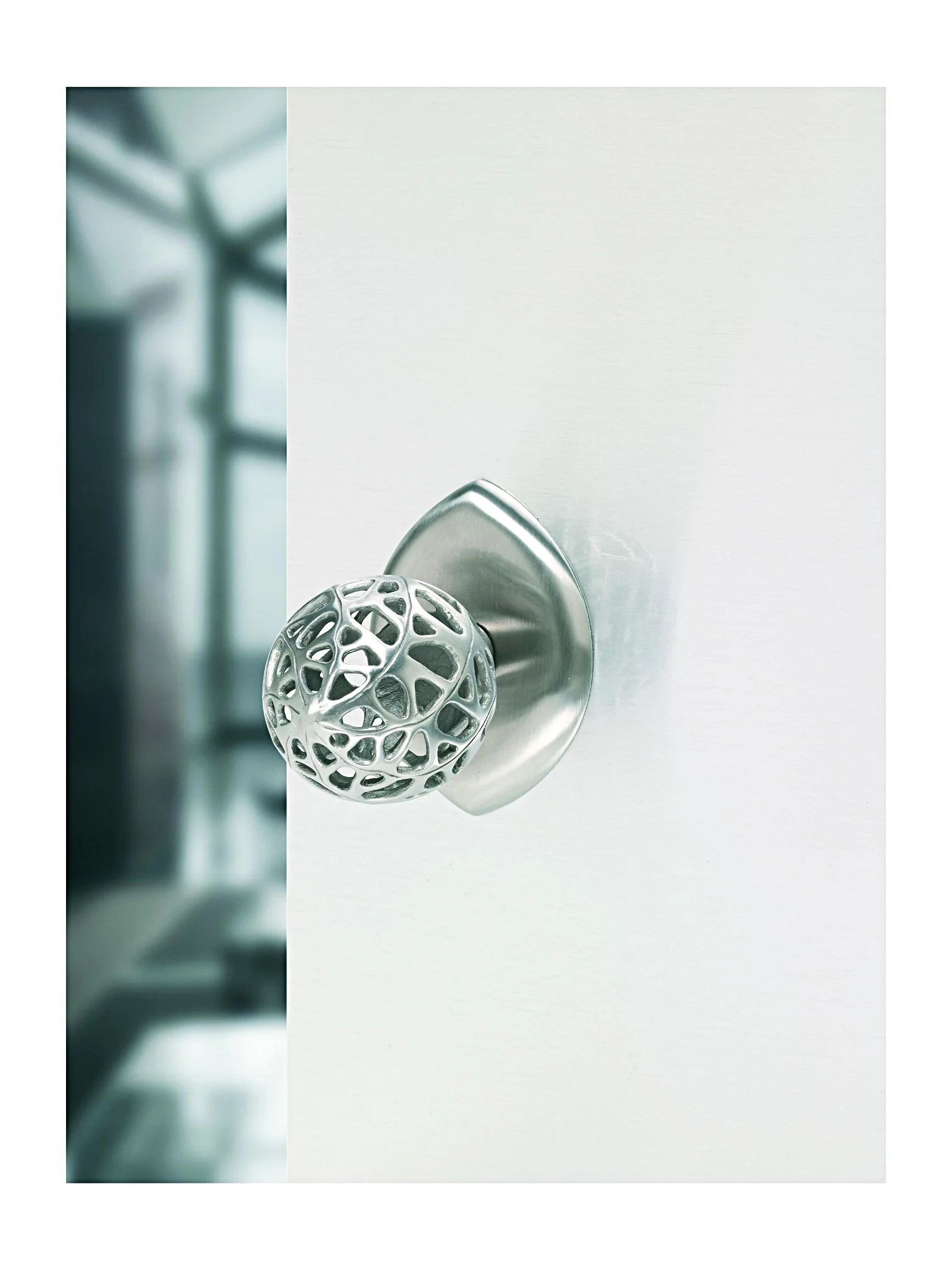

We really enjoy working with creative designers and Bonnie McIntire is one of our favorites in this select group. A couple of years ago we had the pleasure of working with Bonnie and created a hybrid entry door set that combined the willow and lizard collections to produce a Willow Bark entry knob set for a Bel Air residence. This was not an obvious combination of styles, but the result was a playful balanced pairing.

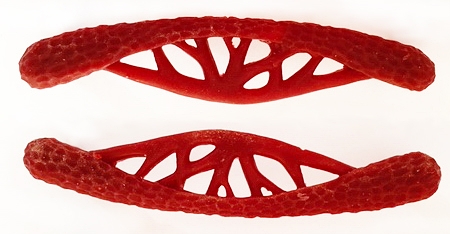

The Willow theme continued through to the kitchen where willow cabinet knobs provided the stopping point for rows of hedgerow branch pulls. While the branch pulls functioned well as pulls for opening drawers, one bank of drawers were situated in a high traffic area where there was little room to pass and to reach the upper cabinets. Unlike cabinet knobs, pulls are generally not self-contained and often the end of the pull for aesthetic balance extends beyond the mounting post and can in confined areas catch on tea towels etc.

Tree Cabinet Handles for other relatives see plant cabinet knob and pulls

When we cast our pieces, we make a wax model and if the number of pieces is not daunting we can make modifications to each wax piece at this stage before the pieces are shelled and cast in bronze. In this case we shortened the top of the pull so that it ended at the mounting post and re-worked the textured indentations and shape to retain aesthetic balance. The result will be a pleasing variation of the branch pull and one that will work with the existing screw holes. If the number of pieces or the amount of labor had been greater then we would have made a new original to incorporate these changes and then created a new mold.

We will keep you posted as we proceed to cast these pieces in bronze.